AIRSKIN technology

Our award-winning AIRSKIN technology is here for the future of human-robot collaboration

Our clients

Simple, yet highly effective

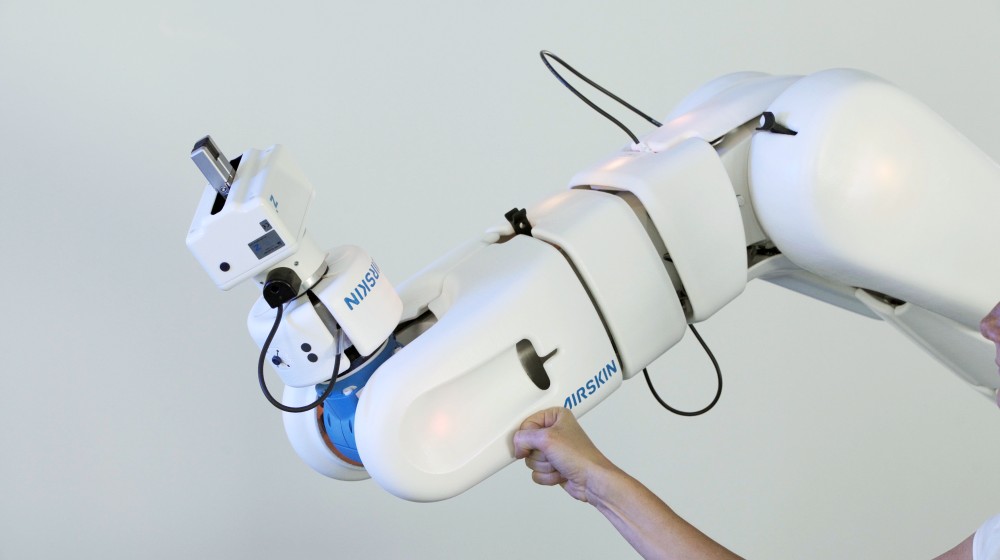

Soft, pressure-sensitive AIRSKIN pads use air as sensing medium to detect collisions, enabling a safe workspace where humans and robots can collaborate freely.

Highest industrial safety rating

Certified to meet EN/ISO 13849-1 (PL e / Cat. 3) and EN/IEC 62061 (SIL 3). Over the past 3 years AIRSKIN has helped customers achieve a more fence-free work environment.

Turning industrial robots into collaborative

AIRSKIN covers all collision areas on the robot. It also helps eliminate clamping and shearing risks of the robotic application and associated tooling. AIRSKIN was designed to meet ISO 10218 and ISO/TS 15066 standards.

About AIRSKIN

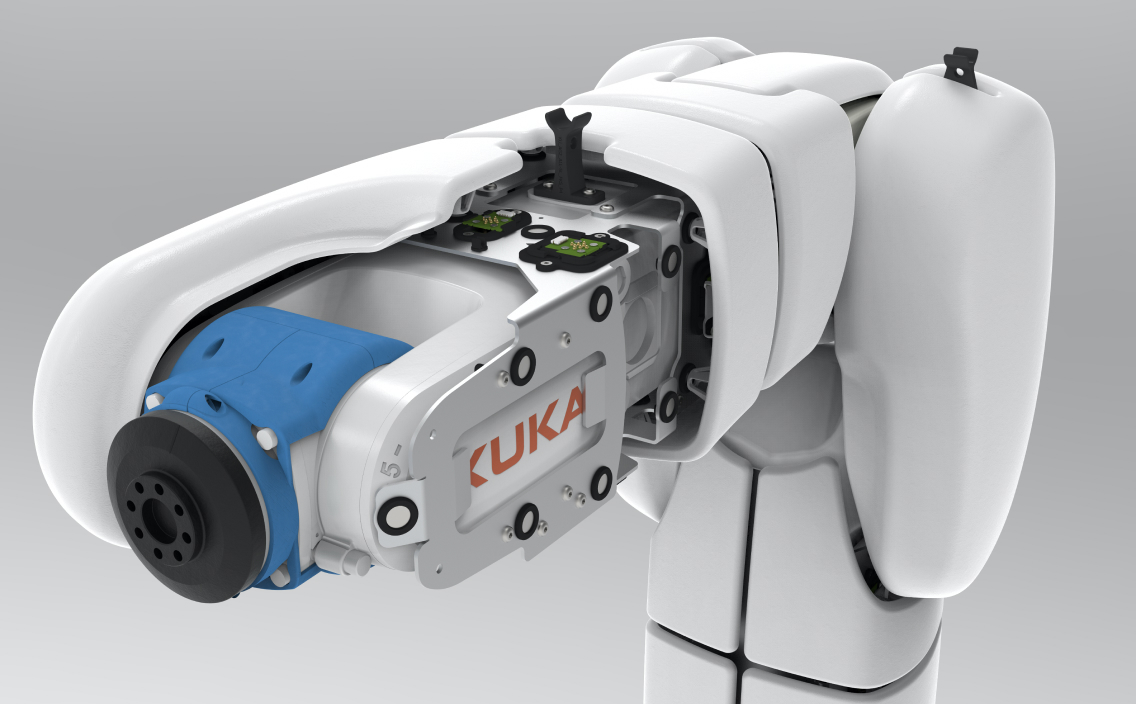

AIRSKIN is an add-on, modular safety solution to upgrade industrial robots and EoAT with pressure-sensitive sensors. An AIRSKIN pad is a soft, thin, airtight skin over a flexible dampening structure with smart safety electronics.

The sensors and pads

Dual channel pressure sensors inside the hull detect pressure changes when the pad is deformed as the result of a contact anywhere on the pad surface. Each pad monitors correct operation by maintaining an internal overpressure of 400 pascal using an integrated piezo-electric micro pump. All pads are connected in series and monitor each other's presence every 4 ms.

Sensitivity

The skin's sensitivity is independent of the contact region, meaning regardless where you come in contact with the AIRSKIN, the robot will go into safety rated protected stop. This occurs with 5 Newtons. AIRSKIN is equally effective for robots regardless of reach and payload.

More about AIRSKIN technology

AIRSKIN functionality

AIRSKIN is easy to install and connect. First a support structure is mounted on your current industrial robot using pre-existing screw locations. No modification is required to your robot. Then all you need to do is magnetically connect the AIRSKIN Modules to the support structure and connect the modules using our proprietary 6-pin magnetic connection cables.

Simple configuration

AIRSKIN acts as an OSSD device and connects directly to the safety inputs of your robot controller, or a safety PLC, using 24V for power supply and signals. No further configuration is required.

Safe collisions

AIRSKIN is a certified safety device (EN/ISO 13849-1 PLe / Cat. 3 and EN/IEC 62061 SIL 3) and will detect all collisions with the robot (free-space, clamping and shearing) and bring the robot to a safety rated protective stop.

Pressure

To activate AIRSKIN, only 5N of force is needed. The soft, thick pads will dampen collisions, absorb collision energy and avoid any high local pressures (see force and pressure limits in the ISO/TS 15066).

Collaborative applications

AIRSKIN enables your industrial robot to achieve ISO/TS 15066 compliant collaborative applications.

More about AIRSKIN® technology

How to use AIRSKIN

AIRSKIN helps you turn an industrial robot application into a collaborative application. AIRSKIN effectively covers all hazardous collision areas. The maximum speed for the robot is based on a risk assesement.

Free-space collisions

AIRSKIN can help large payload robots achieve movement speed of beyond 1 m/s, while still maintaining operator safety. The AIRSKIN Modules help absorb energy and distribute the contact forces associated, helping them avoid serious injury.

Clamping/shearing collisions

For clamping/shearing collisions the robot’s stopping distance must be shorter than the thickness of the soft AIRSKIN. In order to accomodate these stringent application areas, a risk assessement needs to be done to determinate the permissible speed. It must be obtained by measuring contact forces occurring in the collision using an ISO/TS 15066 compliant measurement device.

Increase speed when free of obstructions

You can select the robot speed according to the potential collision hazard associated with your manufacturing process. The robot system can achieve full production speeds when the area is free of potential hazards. When paired with an area scanner we can automatically adjust movement speeds accomodate changing circumstances.

More about AIRSKIN technology

Features

Dual channel OSSD safety device

AIRSKIN is a PLe / Cat. 3 safety device which is easily connected via its 6 wires to any safe I/O of any robot controller.

Magnetically connected moduls

AIRSKIN modular pads are held into place using special rare earth NdFeB N52 magnets. Electrical wiring is daisy-chained via our proprietary 6-pin IP54 magnetic plugs. This system enables you to simply add additional safety modules.

Smart Modules

Each AIRSKIN Pad has a small micro pump that helps achieve a small over pressure of 0.058 PSI / 0.004 Bar. This small overpressure allows us to detect any deformation as a protective stop condition. These modules also communicate with all other pads on the robot system. In addition, there is also embedded LEDs that help operators and plant managers understand the current status of the robot work cell from across the factory floor.

How AIRSKIN works

Save costs and increase ROI by upgrading your applications with AIRSKIN

• Save production space

• Build flexible, mobile work-cells

• Eliminate fences and laser scanners

• Work alongside moving production lines

• Use long reach and high payload robots with short cycle times

• Optimize the use of human skills and their flexibility by adding robotics

• Reduce implementation time by maintaining the same programming interface for the integrator

Start your true human-robot

collaboration with AIRSKIN

Frequently Asked Questions

-

Make sure your robot is ready for ISO/TS 15066, meaning safe position and speed monitoring. With KUKA robots the required feature is called Safe Operation.

-

Up to 15 AIRSKIN pads can be connected in a series. On larger robots, for example Cybertech, we use four lanes with 12 pads on each lane, grouping them into "gripper", "axis 4-6" and so on.

-

Permissible speeds are obtained from ISO/TS 15066 using a formula involving robot mass and payload weight.

-

As with any robot application a risk analysis is mandatory. With AIRSKIN® the procedure is the same as using a lightweight cobot: identify possible collision zones and measure force and pressure. Set the robot speed at this position to meet the threshold in the ISO/TS 15066.